Photo Gallery

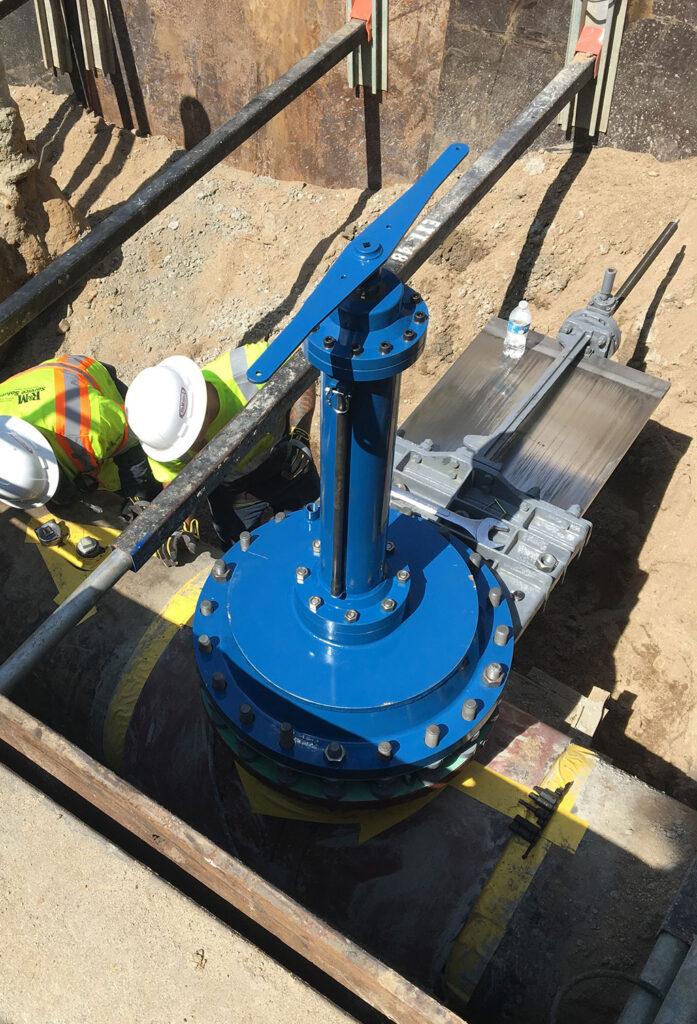

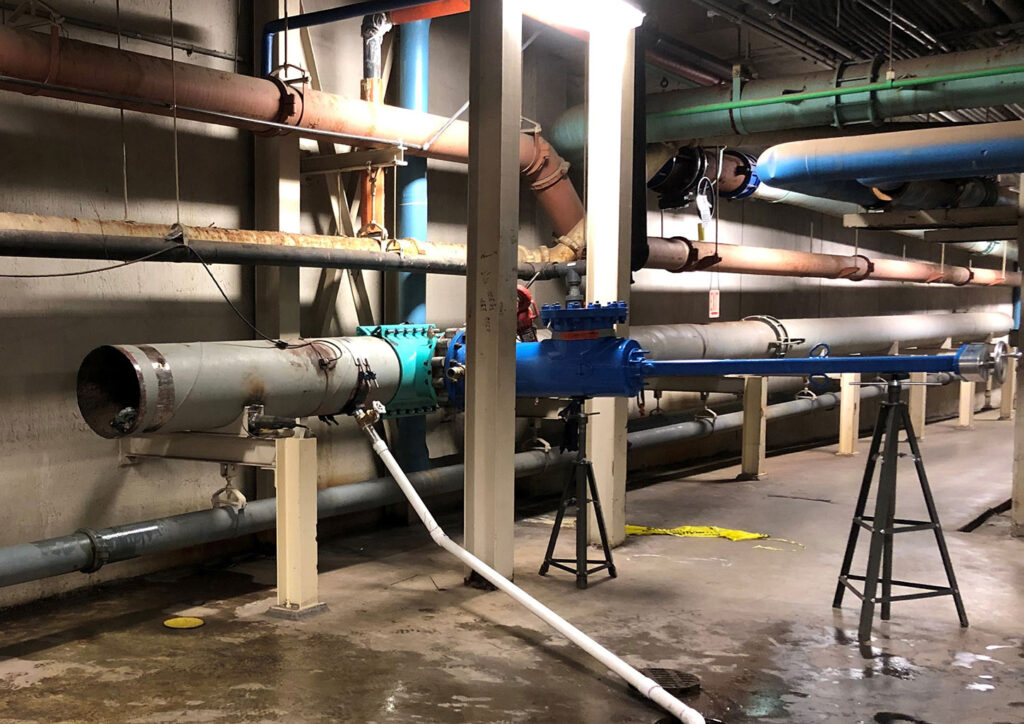

Professional Quality in the Field

TapMaster tapping with the TM300

TapMaster performing a double 16″ linestop

Rangeline performing a double 36″ linestop with a bypass

TapMaster performing a 30″ hot tap with the TM300

Rangeline achieving full shutdown on a 42″ sewer linestop with a bypass

Rangeline performing a 42″ bypassed sewer linestop

TapMaster perfroming a double 16″ linestop outdoors

TapMaster masterfully tapping into the side of a building

WaterTap performing a hot tap with a stretched C1-36

Coupon Retention for Rangeline’s 36″ tap, using Schallert’ diamond segmented saw

Rangeline performing a 36″ hot tap with the TM6120 tapping machine

Rangeline performing a 36″ hot tap with the TM6120 tapping machine

Rangeline completing a 30″ linestop using the PS1836 large plug setter

Rangeline performing a 42″ linestop

WaterTap performing a 12″ linestop indoors

Schallert Enterprises shipping a turn-key double 48″ Folding Head package

WaterTap performing a 12″ linestop indoors

Rangeline performing a double 36″ linestop

Rangeline gearing up for a big double linestop job

Advanced Flow Technologies prepping the TM300 for a hot tap

WaterTap performing a 12″ bypassed linestop

Garrison performing a bypassed double 20″ linestop

TapMaster showing coupon retention for a completed 30″ tap

Pacific Flow Control performing a 20″ linestop indoors

TapMaster performing a 14″ linestop indoors

Rangeline setting up a 66″ Folding Head unit

Coupon Retention with tuberculation

TapMaster line stopping off a wall

TapMaster using the TM300 for performing a tap for valve insertion

TapMaster using the TM300

TapMaster using the TM300

Advanced Flow Technologies performing a tap indoors with the TM300

Rangeline setting up for a big tap

Rangeline inspects their cutter and pilot drill prior to use

Rangeline attaching their hot tap machine and adapter to a valve

Rangeline performing a large diameter tap

Successful coupon retention

Watertap making a 36″ tap with the TM400

Watertap making a 36″ tap with the TM400

Watertap 36″ coupon retention

Koppl using a 20″ folding head with a 12″ bypass

Rangeline using the TM200

Rangeline using the 30″ Folding Head with a 24″ bypass

TapMaster using the TM300

TapMaster completing the job with a completion plug setter

Rangeline using the TM250 for a tap

Rangeline using the TM300 for a tap

Rangeline performs a 14″ linestop with a 12″ bypass

Culy Contracting using the TM100

Rangeline using the C136 Stretch machine to perform a tap

60″ carbide tipped cutter and pilot drills ready to ship to a customer

TapMaster using the TM100

Koppl using the TM100 indoors

TapMaster getting creative with an angled 16″ bypassed linestop

TapMaster using the Model 36 electric tapping machine

Rangeline saving the day with a 12″ linestop on a water main break caused by Hurricane Ian

Rangeline doing a tap with a C1-36 stretch machine